Innovation in Action: Our Next-Gen Catalyst Facility is Here!

At Neocat, innovation isn’t just a goal—it’s the way we move forward. We’re proud to announce the launch of our new state-of-the-art facility, a space designed to bring bold ideas to life and accelerate the future of catalyst development.

Why this is a game-changer:

Innovation at the Core – With advanced equipment, proprietary processes, and the ingenuity of our team, our expanded facility strengthens our R&D capabilities to deliver catalysts with unmatched precision and performance—for industries ranging from pharmaceuticals and food processing to specialty chemicals, fuel cells, and gas purification.

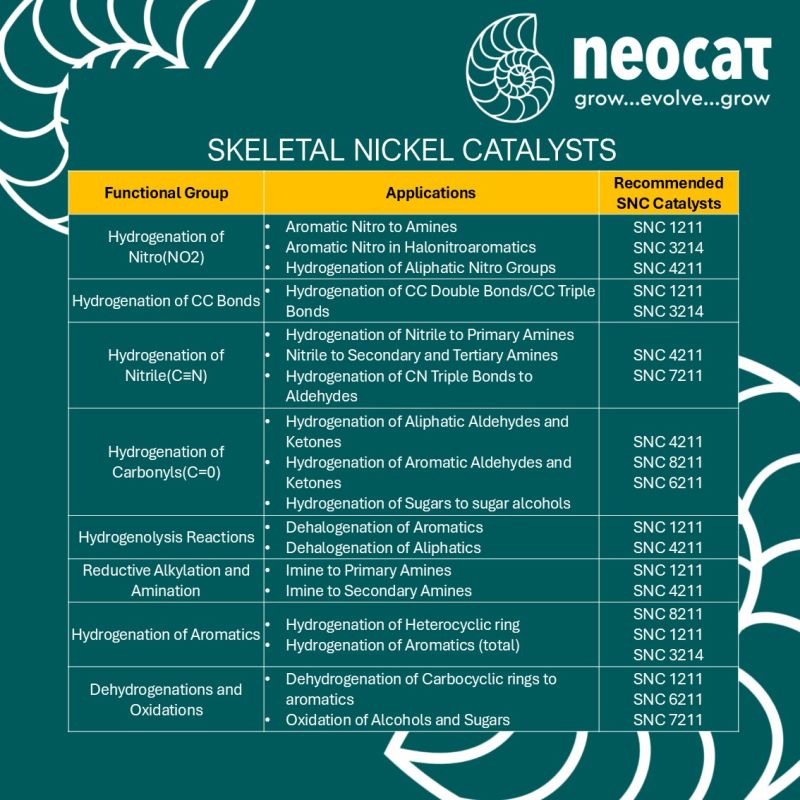

Introducing NEOCAT's Skeletal Nickel Catalysts (Raney-Type)

At Neocat, we see catalysis as the key to making complex chemistry more efficient, reliable, and sustainable. That’s why, we’ve developed different grades of Skeletal Nickel Catalysts with high surface area, superior hydrogenation activity, and excellent selectivity—delivering consistent results across multiple products and industries.

Key advantages:

High Surface Area & Efficiency – Porous structure created through selective leaching enables highly effective hydrogenation reactions.

Broad Industrial Utility – Trusted for various hydrogenations, such as, C=C bond

At Neocat, our Homogeneous Catalysts based on Palladium

At Neocat, our Homogeneous Catalysts based on Palladium (Pd), Platinum (Pt), Rhodium (Rh), and Ruthenium (Ru) are designed to deliver precision and selectivity at the molecular level. These catalysts enable faster reaction rates, cleaner conversions, and higher yields across diverse industries. Some applications across Industries: Pharmaceuticals – Palladium acetate and Pd(PPh₃)₂Cl₂ drive C–C coupling reactions like Suzuki, Heck, and Stille for complex API intermediates. Agrochemicals – Ruthenium trichloride and Ru(acac)₃ support olefin metathesis and nitrile hydrogenations for crop-protection agents. Specialty & Perfumery – Platinum(0) complexes enable efficient hydrosilylation, producing high-value silicones and fragrance intermediates. Fine Chemicals – Rhodium chloride and Rh₂(OAc)₄ are key in asymmetric hydrogenations, producing enantiopure alcohols and amines.

From pharma to flavorings - see how Neocat’s catalysts power the world’s most critical reactions.

Our heterogeneous catalysts, based on Palladium on Carbon (Pd/C), Platinum on Alumina (Pt/Al₂O₃), Rhodium on Carbon (Rh/C), and Ruthenium on Carbon (Ru/C), are trusted workhorses for commercial hydrogenation and oxidation processes. Anchored on solid supports, they combine activity, durability, and simplified separation. Applications Across Industries: Pharmaceuticals – Palladium on Carbon enables nitro-to-amine hydrogenations for intermediates in analgesics and cardiovascular drugs. Agrochemicals – Platinum oxide (PtO₂) and supported Pt/Al₂O₃ reduce carbonyl groups to alcohols in crop-protection molecules. Food & Perfumery – Ruthenium on Carbon catalyzes hydrogenation of aromatic rings (e.g. benzene to cyclohexane), a key step in producing flavorings and nylon precursors.